Biological odor and emission treatment systems have seen growing favor among industrial facility managers in search of a clean, sustainable and potentially cheaper way to treat unpleasant or dangerous air.

These systems have clear advantages: Bacteria and other microorganisms are used in the breakdown of offending compounds instead of absorbing them with activated carbon (which requires constant replacement) or chemicals (which are costly and often dangerous). The bacteria and microorganisms inside biotrickling filters and bioscrubbers do not need to be replaced.

Similarities between biotrickling filters and bioscrubbers abound, but the subtle difference between the two has major performance implications.

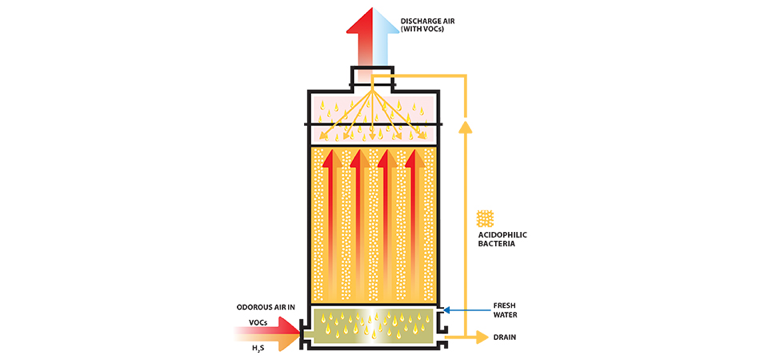

Bioscrubbers

These odor and emission treatment systems rely on microorganisms present in the water that’s recirculated through the treatment vessel. Foul air is forced upward through the bottom of the vessel. On its way up, it’s dispersed through synthetic media and contacts the water laden with microorganisms.

The microorganisms metabolize the offending compounds, leaving clean air to be released from the vessel.

Water recirculation is the key feature of bioscrubbers. The water retains all the metabolized compounds removed from the air, increasing its acidity. While that acidity supports the growth of some microorganisms, not all types can thrive in the acidic environment.

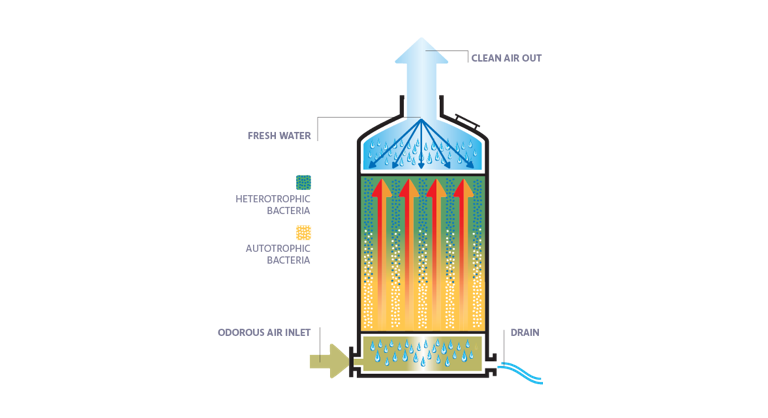

Biotrickling filters

These systems work similarly in that they use microorganisms, media and water. Odorous or polluted air is collected and forced up through structured media within the vessel. But in biotrickling filters, the microorganisms grow within the media.

The key differentiator of biotrickling filters is that they do not recirculate water. The water used in these systems passes through only once, and acts mainly as a rinse to drain the metabolized compounds away. And while at first glance this might seem inefficient, biotrickling filters and bioscrubbers actually use identical amounts of water to treat identical airflows.

Research has shown that biotrickling filters support a greater diversity of bacteria. As impacted air is forced upward through the vessel, it encounters different types of microorganisms. That diversity has been shown to eliminate more, and more kinds, of the compounds produced in industrial processes. This is why biotrickling filters can remove a host of compounds —such as H2S, NH3, volatile fatty acids, organic odors and select VOCs— with great efficiency.

In addition to being more effective than bioscrubbers, biotrickling filters also are less expensive, have lower operating costs, and are easier to maintain because they do not include the extra pumps and piping necessary for water recirculation.

Biotrickling filters from BioAir Solutions

BioAir Solutions often recommends EcoFilter® biotrickling filter systems to meet customers’ industrial odor and emission control needs.

These systems feature cutting-edge EcoBase® structured media with engineered flow channels that promote efficient, speedy treatment of odorous air. A partnership with BioAir means we take on your odor or emission challenges and develop a custom BioAir Complete® solution that meets your site’s unique needs.

To speak with a process engineer about our BioAir Complete services or to request an on-site consultation, contact us anytime.

If you’re still researching, our introductory guide to industrial odor control is a great resource.