EcoClear® VOC Treatment Technology

Biological VOC treatment in a sustainable and environmentally friendly manner, at a fraction of the carbon footprint and cost of thermal oxidation.

How it works

1 OF 4

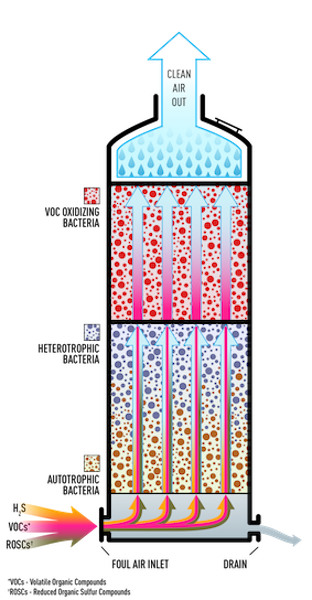

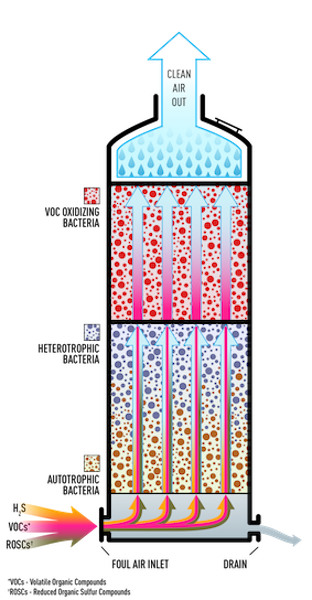

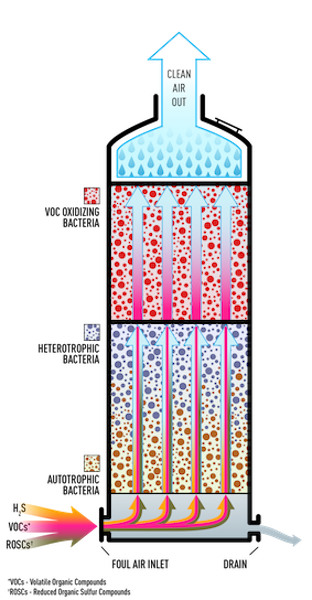

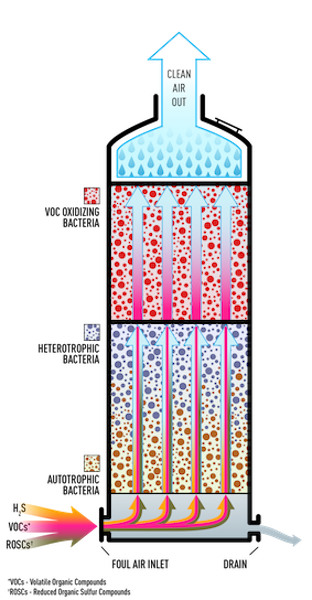

1. Foul Air

Our EcoClear® systems are designed to treat hazardous and regulated volatile organic compounds (VOCs) such as benzene, toluene, ethylbenzene and xylene (BTEX) from polluted air streams. Based on the type of VOC compounds in the foul air, we develop a custom, often multi-stage solution capable of biologically treating VOCs along with other compounds such as hydrogen sulfide (H2S) and reduced organic sulfur compounds (ROSCs) that frequently coexist with VOCs. The air is forced into or pulled through the EcoClear vessel where it begins its treatment in the first stage.

“But don’t just take our word for it. Learn how EcoClear® VOC helped these two companies find their own path to sustainable carbon footprint reduction.”

2 OF 4

2. EcoBase Plus Media

Air entering the EcoClear vessel travels upward through our proprietary EcoBase® Plus synthetic and structured media – the heart of our biotrickling filter technology. Unique features of EcoBase Plus over conventional polyurethane foam (PUF) and other inorganic random media, include high surface area to treat high VOC loadings, pre-engineered flow channels for mass transfer optimization and consistent performance, and special biological adhesion properties allowing EcoClear biotrickling filters to host trillions of microorganisms that consume unwanted pollutants. By using biology that “works for free” rather than energy-consuming thermal oxidation, EcoClear biotrickling filters significantly reduce your carbon footprint and operating cost.

“But don’t just take our word for it. Learn how EcoClear® VOC helped these two companies find their own path to sustainable carbon footprint reduction.”

3 OF 4

3. Multi-Stage Biological Treatment

EcoClear often consists of multiple process stages. In comparison to single-stage biotrickling filters, EcoClear allows for the cultivation of bacterial species specifically needed for the oxidation of specific targeted VOC compounds. It has more advanced process controls to control the conditions within the media top optimize the growth of the bacteria needed consume the VOCs. Irrigation water with EcoGrow® nutrients are introduced at the top of each process stage and trickles down through the EcoBase Plus media, providing necessary moisture for the bacteria and to remove the metabolized byproducts of VOC oxidation. BioAir’s EcoGrow® nutrients keep the microorganisms healthy and thriving by providing the needed macro- and micronutrients for optimal bacterial health and growth.

“But don’t just take our word for it. Learn how EcoClear® VOC helped these two companies find their own path to sustainable carbon footprint reduction.”

4 OF 4

4. Clean Air

After treatment, the air exits the EcoClear via a stack at the top of the reactor. EcoClear systems are designed to eliminate more than 99% of many hazardous VOCs and odorous compounds from the polluted air. Once the EcoClear VOC treatment system is installed at your site, a BioAir technical specialist will startup the system and train your staff on its operation and maintenance. Once the system is fully acclimated, the system is performance-tested to verify that EcoClear meets, or exceeds, all the specified treatment efficiencies.

“But don’t just take our word for it. Learn how EcoClear® VOC helped these two companies find their own path to sustainable carbon footprint reduction.”

Key advantages

1

Low Carbon footprint

2

Very low operating cost

3

Environmentally friendly VOC treatment technology

4

Eliminates need for natural gas supply

5

Easy to operate and maintain

6

Does not produce SOx or NOx emissions

Popular applications

BioAir’s EcoClear biological VOC treatment system offers a sustainable and environmentally friendly alternative to VOC emission control applications that traditionally would utilize direct-fired or regenerative thermal oxidizers (DFTO / RTO), at a fraction of the carbon footprint. This includes Oil and Gas applications (including refineries), painting and coating operations, waste-to-energy facilities, pharmaceutical, food processing and many more. EcoClear can treat a wide range of VOCs including BTEX compounds, volatile fatty acids, styrene, alcohols.

Some states and municipalities have eliminated or restricted new natural gas supply hookups for thermal oxidizers, making EcoClear VOC treatment technology an absolute essential. Furthermore, EcoClear provides significant benefits over thermal oxidizers such as reduced OPEX and carbon footprint. Contact us to discuss the specifics of your application – we will be happy to help.

Letʼs talk

Explore other BioAir products

BioAir Solutions offers many different odor and emission treatment options, each tailored to the unique challenges you face.